Steel drums are fascinating musical instruments with a unique sound. But how exactly are they made?

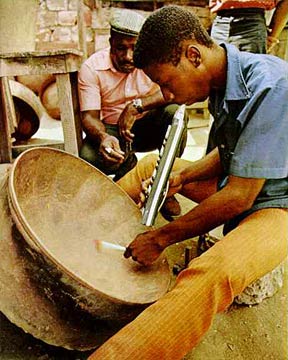

Steel drums, also known as steel pans, originate from Trinidad and Tobago. They are crafted from metal oil barrels. The process of making a steel drum involves several steps. First, the barrel top is stretched and shaped. Then, skilled artisans carefully hammer the metal to create different notes.

Each step is crucial for producing the drum’s distinctive tones. This detailed craftsmanship results in the beautiful music we hear from steel drums. Understanding the process gives us a deeper appreciation of these musical instruments. Let’s explore the journey of steel drums from oil barrels to melodic masterpieces.

Credit: www.youtube.com

Introduction To Steel Drums

Steel drums, often known as steel pans, are fascinating musical instruments. They produce unique, melodic sounds that captivate listeners. Steel drums originated in the Caribbean and have a rich cultural history. This blog section explores their history and uses.

History Of Steel Drums

Steel drums have their roots in Trinidad and Tobago. During World War II, the use of traditional African drums was banned. People innovated by using oil barrels to create music. They hammered the barrels to different shapes to produce various notes. This gave birth to the steel drum.

Over time, the craft of making steel drums evolved. Skilled artisans learned to fine-tune the drums for better sound. Today, steel drums are recognized globally. They symbolize resilience and creativity.

Uses Of Steel Drums

Steel drums are versatile instruments. They are used in many music genres. Caribbean music, especially calypso, heavily features steel drums. They add a vibrant, rhythmic element to the music.

Besides music, steel drums are also used in education. Schools use them to teach rhythm and musical harmony. They are easy to learn and play, making them popular among students.

Steel drums also find a place in therapy. Their soothing sounds help in stress relief and relaxation. Many therapists use them for their calming effects.

Credit: www.toucans.net

Materials Used

Steel drums are iconic musical instruments known for their vibrant sound. Making them requires specific materials to ensure quality. Understanding the materials used is vital for appreciating the craftsmanship behind these drums.

Types Of Steel

Steel drums are crafted from different types of steel. Most commonly, manufacturers use low-carbon steel. This type of steel is preferred for its durability and malleability. It allows artisans to shape the drum without compromising its strength. Some makers also use medium-carbon steel. This steel type offers a balance between hardness and ductility. Both types ensure the drum produces clear, resonant tones.

Other Essential Materials

Besides steel, other materials are crucial in making steel drums. One key material is the protective coating. This coating prevents rust and enhances the drum’s appearance. Common coatings include paint and chrome plating. Another important material is the tuning tool. Craftsmen use these tools to fine-tune each drum. Proper tuning ensures the drum produces the desired notes. Additionally, rubber pads are used. These pads are placed on the drum’s stands to reduce vibrations and improve sound quality.

Designing Steel Drums

Designing steel drums involves careful planning and attention to detail. These instruments are not just about the music they produce, but also their shape and size. The design impacts the sound quality and the ease of play. Let’s dive into some key aspects.

Shape And Size

The shape and size of a steel drum greatly influence its tone. Larger drums often produce deeper sounds. Smaller drums have higher pitches. The curvature of the drum’s surface also matters. A well-crafted shape ensures good resonance. The drum’s height and diameter need to be balanced. This balance helps achieve the desired sound.

Acoustic Considerations

Acoustic properties are key in designing steel drums. The material used affects the sound. Steel is the preferred choice due to its durability and resonance. The drum must be tuned accurately. This tuning process involves creating precise indentations. These indentations correspond to different notes. Proper tuning ensures each note is clear and distinct.

Harmonics play a role as well. These are the overtones that add richness to the sound. A well-designed drum will have a balance of fundamental tones and harmonics. This balance makes the music pleasant to the ear. Each drum is unique. Designers must keep this in mind during the creation process.

Cutting And Shaping

Steel drums, known for their distinct sound, are crafted with precision. The process involves several stages. One crucial stage is cutting and shaping. This step ensures the drum achieves its perfect form and sound quality.

Cutting Techniques

The first step in shaping steel drums is cutting the steel. Workers use various cutting techniques. One common method is plasma cutting. This technique uses high-temperature plasma to cut through steel. It is fast and precise.

Another method is laser cutting. Laser cutting uses a focused beam of light. This light cuts the steel with great accuracy. Both methods ensure the drum pieces are the right size and shape. The goal is to make the cuts smooth and exact.

Forming The Drum Body

After cutting, the steel pieces need shaping. Workers use machines to form the drum body. One key machine is the hydraulic press. This press bends the steel into a cylindrical shape. The cylinder will become the main body of the drum.

Next, workers weld the edges together. Welding creates a strong, seamless bond. This step ensures the drum’s durability. The drum now has a basic shape. Further shaping and tuning will refine it.

Forming the drum body is a crucial step. It influences the drum’s final sound and quality. Skilled workers and precise machines make this possible. The result is a well-formed, high-quality steel drum.

Welding And Assembly

The welding and assembly process is crucial in the production of steel drums. This stage ensures that all parts are securely joined, and the drum is ready for use. Let’s delve into the steps involved in joining components and ensuring structural integrity during the assembly of steel drums.

Joining Components

The first step in assembly is joining components. Steel drums have several key parts, including the body, top, and bottom. These parts are welded together to form a single unit.

Here is a table that explains the parts:

| Component | Description |

|---|---|

| Body | The cylindrical part of the drum. |

| Top | The upper lid, often with openings for filling. |

| Bottom | The base of the drum, providing stability. |

Welders use specialized equipment to ensure precise welding. This equipment includes:

- Welding machines

- Protective gear

- Clamps and jigs

Welders align the parts carefully before welding. They use clamps and jigs to hold the components in place.

Ensuring Structural Integrity

Ensuring the structural integrity of the drum is a critical step. Poor welding can lead to leaks or weak points.

To ensure strength, welders follow these steps:

- Inspect welds visually and with tools.

- Perform leak tests using air or water.

- Check for uniformity in weld seams.

Each drum undergoes these tests before moving to the next stage. This ensures that every drum meets quality standards.

In summary, the welding and assembly of steel drums involves precise joining and thorough inspection. This process ensures that the drum is strong, durable, and ready for use.

Tuning The Drum

Steel drums, also known as steel pans, require precise tuning. This process ensures the drum produces the correct musical notes. Tuning involves careful hammering and shaping of each note area. It’s a craft that demands skill and patience.

Tuning Techniques

Several techniques are used to tune steel drums. One common method is the use of a tuning hammer. The tuner strikes the metal to adjust the pitch. Another technique involves using electronic tuners to measure the accuracy of each note.

Experienced tuners can also rely on their ears. They listen closely to the sound each note produces. Through repeated adjustments, the tuner refines the pitch until it reaches the desired tone.

Achieving Desired Sound

Achieving the desired sound is a meticulous process. Each note area, or “dimple,” must be tuned individually. The tuner shapes the dimples to resonate at specific frequencies.

The goal is to produce clear, melodic tones. The final sound depends on the precision of the tuning. Even small adjustments can significantly impact the overall sound quality.

Tuning is not just about hitting the right notes. It’s about creating harmony and balance across the drum. Each note must blend well with others to create a pleasing musical experience.

Finishing Touches

The final steps in making steel drums are crucial. These steps ensure that the drums are not only functional but also visually appealing. The finishing touches include polishing, painting, and adding decorative elements. Each step enhances the durability and beauty of the steel drum.

Polishing And Painting

Polishing the steel drum gives it a smooth and shiny surface. This process removes any rough edges or imperfections. The drum is then painted to protect it from rust and corrosion. Paint also adds color and can be customized based on preferences.

Adding Decorative Elements

Decorative elements make each steel drum unique. These elements can include stickers, engravings, or even hand-painted designs. They personalize the drum and can reflect the culture or style of the maker. These details not only beautify the drum but also tell a story.

Quality Control

Quality control is a crucial step in the production of steel drums. Ensuring each drum meets high standards is essential. This process involves thorough inspection and testing.

Inspection Processes

First, the drums undergo visual inspection. Workers check for dents, scratches, and other defects. They also ensure the drums meet size specifications. Any drum that fails the inspection is set aside for correction.

Next, inspectors measure the thickness of the steel. They use precise tools for accurate readings. Consistency in thickness is vital for durability and sound quality.

Testing For Sound Quality

Sound quality is a key feature of steel drums. Each drum is tested for its musical tone. Skilled tuners strike the drum with a mallet. They listen for the correct pitch and tone. Adjustments are made until the drum produces the desired sound.

Electronic devices also assist in sound testing. These devices measure frequency and vibrations. Combining human skill with technology ensures high-quality sound.

Drums that pass both inspection and sound tests are ready for packaging. They are then shipped to musicians and customers worldwide.

Environmental Considerations

Steel drum manufacturing has evolved to become more environmentally friendly. Environmental considerations play a vital role in the production process. These efforts help in reducing the carbon footprint and preserving natural resources.

Sustainable Practices

Many steel drum manufacturers use sustainable practices. They source raw materials from suppliers who follow eco-friendly methods. These methods include reducing emissions and conserving energy. Using renewable energy sources is also common.

Manufacturers aim to minimize waste during production. They use advanced technologies to make the process more efficient. These technologies include energy-efficient machinery and precise cutting tools. This reduces the amount of scrap metal produced.

Recycling And Waste Management

Recycling is a key part of steel drum manufacturing. Recycling and waste management help in reducing the need for new raw materials. Many manufacturers use recycled steel in their production process. This reduces the need for mining and conserves natural resources.

| Practice | Benefit |

|---|---|

| Using Recycled Steel | Reduces mining and saves resources |

| Waste Management | Minimizes landfill waste |

Efficient waste management systems are also in place. These systems sort and recycle waste materials. This reduces the amount of waste sent to landfills. Some manufacturers even recycle water used in the production process.

Overall, steel drum manufacturers are committed to protecting the environment. Sustainable practices and recycling are at the core of their operations. This ensures that steel drum production is as eco-friendly as possible.

Credit: www.caribbean-steel-drums.com

Frequently Asked Questions

What Is The Process Of Making Steel Drums?

Steel drums are made by cutting and shaping large steel sheets. They are then welded and sealed.

How Is Steel Formed Into Drums?

Steel is heated, molded, and cooled to form drum shapes. The process ensures durability.

What Materials Are Used For Steel Drums?

Steel drums are primarily made from high-quality carbon steel. This ensures strength and longevity.

How Are Steel Drum Lids Made?

Steel drum lids are stamped and shaped from steel sheets. They are then securely attached.

Conclusion

Steel drum making is an intricate yet fascinating process. Skilled craftsmen shape, tune, and test each drum. The result is a beautiful, resonant instrument. Understanding this process adds appreciation for the music they create. Steel drums bring joy and cultural richness worldwide.

They symbolize craftsmanship and musical heritage. Next time you hear their sound, remember the artistry involved. Embrace the unique journey of steel drum creation. It’s a testament to human ingenuity and passion for music.