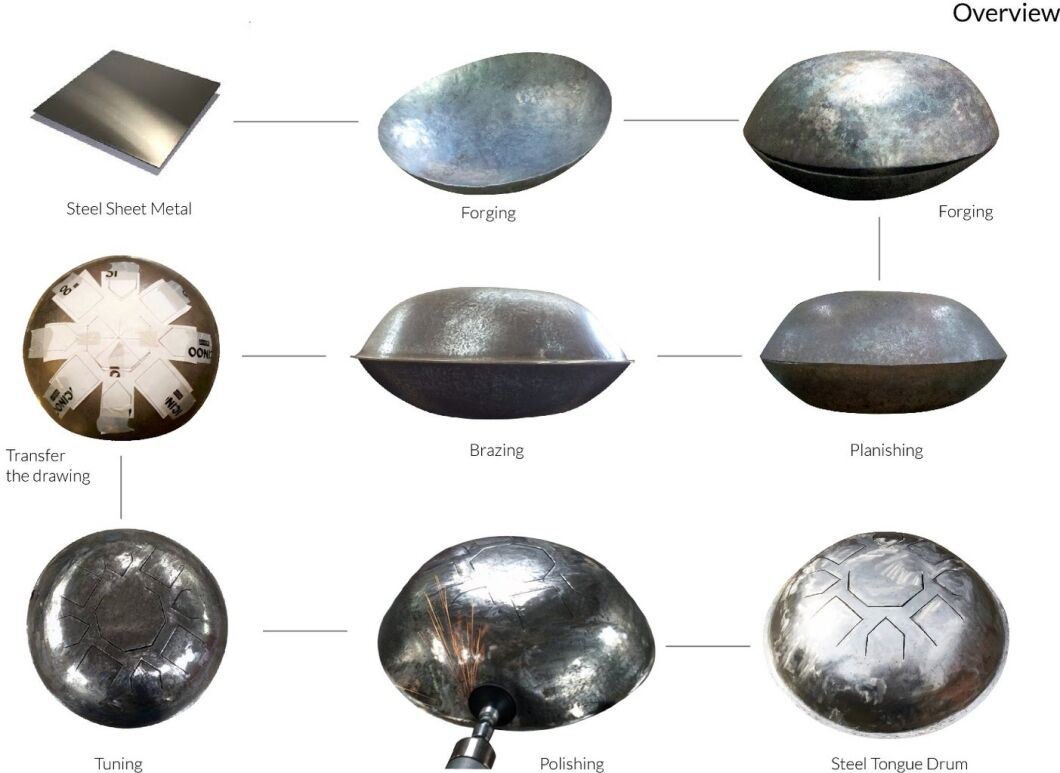

Making a steel drum involves several steps. It requires skill, patience, and the right tools.

Steel drums, also known as steel pans, are unique musical instruments. They originate from Trinidad and Tobago. These drums create a distinct sound that captivates listeners. Crafting a steel drum is both an art and a science. It begins with selecting the right steel barrel.

Then, the barrel is shaped, tuned, and tempered. Each step is crucial to the final sound quality. In this blog post, we’ll explore the process of making a steel drum in detail. You’ll learn about the materials, tools, and techniques needed. By the end, you’ll have a clear understanding of how these fascinating instruments come to life.

Credit: www.instructables.com

Introduction To Steel Drums

Steel drums, also known as steel pans, originate from the Caribbean. These unique instruments create mesmerizing music. But how are they made? This blog will explore the process.

Brief History

Steel drums were invented in Trinidad and Tobago in the 1930s. They evolved from African drumming traditions. Early steel drums were made from discarded oil barrels. Musicians hammered the bottoms to create different pitches. Over time, the process became more refined. Today, steel drums are crafted with precision and skill.

Popularity And Uses

Steel drums gained popularity worldwide. They are used in many music genres. You can hear them in calypso, reggae, and jazz. They add a unique sound to any ensemble. Steel drums are also used in educational settings. Students learn about rhythm and melody through these instruments.

| Genre | Use of Steel Drums |

|---|---|

| Calypso | Main instrument |

| Reggae | Accent and melody |

| Jazz | Improvisation |

In summary, steel drums are fascinating instruments with a rich history. Their unique sound captivates audiences around the globe.

Materials Needed

Creating a steel drum requires specific materials and tools. Proper selection of these materials is crucial for crafting a high-quality instrument. Let’s dive into the essentials you need to get started.

Steel Selection

The most critical component of a steel drum is, of course, the steel. Here are some key points to consider:

- Type of Steel: Use medium-gauge steel, typically 55-gallon oil drums.

- Condition: Ensure the drum is free from rust and dents.

- Thickness: The steel should be thick enough to withstand shaping but thin enough to resonate well.

Finding the right drum can impact the final sound quality. Make sure to inspect the drum thoroughly before purchasing.

Other Essential Tools

Besides the steel drum, you will need several other tools. These tools help in shaping and tuning the drum. Here’s a list:

- Hammer: A ball-peen hammer for shaping the steel surface.

- Tuning Stick: A tuning stick to fine-tune the notes.

- Template: A note template to mark the note areas accurately.

- Drill: A drill for creating the skirt of the drum.

- Metal Files: Metal files to smooth out any rough edges.

- Sander: A sander to polish the surface.

Having these tools at hand ensures a smoother crafting process. Proper tools contribute to the drum’s overall quality.

| Tool | Purpose |

|---|---|

| Hammer | Shaping the steel surface |

| Tuning Stick | Fine-tuning the notes |

| Template | Marking the note areas |

| Drill | Creating the skirt |

| Metal Files | Smoothing rough edges |

| Sander | Polishing the surface |

Each tool has a specific function. Using them correctly helps achieve the best results.

Shaping The Drum

Shaping the steel drum is a critical part of the drum-making process. It involves forming the drum body and creating the drum face. This step determines the drum’s final shape and sound quality. Let’s dive into the details of each part.

Forming The Drum Body

The drum body starts as a large steel oil barrel. First, clean the barrel thoroughly to remove any residues. Next, cut off the top of the barrel to open it up. This creates the basic structure of the drum. Then, smooth the edges to ensure there are no sharp parts.

Once the barrel is open, the next step is to shape the body. This involves gently hammering the sides to create a more rounded form. This process needs precision. It helps in producing even sound waves. The drum body must be symmetrical for the best sound quality.

Creating The Drum Face

The drum face is the area that produces the sound. First, mark the drum face with a pattern for the notes. This pattern includes circles and lines. It helps in guiding the tuning process later.

Next, use a hammer to create the notes on the drum face. Each note needs careful shaping. The depth and size of each indentation affect the sound. Therefore, take your time with each note. This step is crucial for the final sound quality.

After shaping the notes, smooth the drum face. This ensures a clean surface. It helps in producing clear and crisp sounds.

Credit: www.steelpan-steeldrums-information.com

Marking The Notes

Marking the notes on a steel drum is a crucial step. It ensures each note is placed accurately for proper sound production. This step requires precision and attention to detail. Let’s dive into how to mark the notes effectively.

Note Layout

Start by cleaning the drum surface. Use a marker to draw circles where each note will be. The size of the circle depends on the note’s pitch. Larger circles produce lower notes. Smaller circles produce higher notes. Arrange the notes in a pattern that matches the steel drum type. Follow a specific scale or musical arrangement. This layout helps in both playing and tuning the drum later.

Tuning Requirements

Each marked note must be tuned to the correct pitch. Use a tuner to check each note’s frequency. Adjust the note’s area if the pitch is off. This can mean hammering the area to raise or lower the pitch. Precise tuning ensures the steel drum sounds harmonious. Repeat the tuning process for all marked notes. Consistency is key in achieving a well-tuned steel drum.

Cutting The Notes

Cutting the notes on a steel drum is a critical step. It defines the instrument’s tonal quality and pitch. This process requires careful planning, precision, and the right tools. Each note area is cut to a specific size and shape. This ensures the steel drum produces the desired sound.

Tools For Cutting

To cut the notes, you need specific tools. A metal cutter is essential. It provides the accuracy required for clean cuts. A chisel is useful for refining edges. It can help achieve precise shapes. A hammer is also necessary. It aids in controlling the cutting force. Safety gear is important. Always wear gloves and protective eyewear.

Techniques For Precision

Precision is key in cutting notes. Start by marking the drum with a template. This outlines where each note will be cut. Use the metal cutter to follow these marks. Make small, controlled cuts. This prevents mistakes and ensures accuracy. Use the chisel to smooth and refine the edges. This step ensures the notes have a clear sound.

Take your time with each cut. Rushing can lead to errors. Check your work frequently. Ensure each note is the correct size and shape. Precision cutting produces a high-quality steel drum. The result is an instrument with perfect pitch and tone.

Smoothing And Shaping

Creating a steel drum involves many steps. One important step is smoothing and shaping. This step ensures the drum has a clean, polished look. It also ensures the drum is safe to use. Below, we will explore two key parts of this process: grinding the edges and smoothing the surface.

Grinding The Edges

The edges of a steel drum can be sharp. Grinding the edges makes them smooth. This step is essential for safety. Workers use a grinding tool for this task. They move the tool along the edges of the drum. This action removes any sharp bits. It also makes the drum look neat. Ensuring smooth edges prevents cuts and injuries.

Smoothing The Surface

The surface of the drum also needs attention. It must be smooth for the drum to sound good. Workers use sanders and polishers for this step. They rub these tools over the drum’s surface. This action removes any rough patches. It also gives the drum a shiny finish. A smooth surface helps the drum produce clear, rich sounds. It also makes the drum look appealing.

Tuning The Steel Drum

Tuning a steel drum is an art. It requires patience and precision. This part of the process is crucial. It ensures the drum produces the right notes. A well-tuned drum creates beautiful music. Let’s dive into the steps involved.

Initial Tuning

The first step is initial tuning. This involves rough tuning of the notes. The tuner uses a hammer and a tuning stick. They tap the drum’s surface to shape the notes. Each note must be distinct. This stage sets the foundation for fine-tuning.

The tuner listens carefully. They compare the sound to a reference pitch. They adjust the surface until the pitch matches. This process is repeated for each note area. It can be time-consuming. But it is essential for good sound quality.

Final Adjustments

After initial tuning, the drum needs final adjustments. This is called fine-tuning. The tuner makes small changes to each note. They use electronic tuners or tuning forks. This ensures each note is precise.

The tuner checks the harmonics of each note. Harmonics are the overtones that add richness to the sound. They ensure the drum has a clear, pure tone. They may need to retune several times. This ensures the drum stays in tune.

Once the drum is tuned, it is tested. The tuner plays simple melodies. This checks if all notes sound good together. A well-tuned steel drum creates beautiful, harmonious music.

Finishing Touches

After forming and tuning the steel drum, the final step is adding the finishing touches. These steps ensure the drum is not only functional but also visually appealing and protected from elements. Let’s dive into the crucial aspects of the finishing touches.

Painting And Coating

Painting and coating are essential to protect the steel drum from rust and corrosion. Here’s a simple guide to the process:

- Clean the Drum: Remove any debris, grease, or dirt.

- Apply Primer: Use a primer to prepare the surface. This helps the paint stick better.

- Choose Paint: Select a durable, high-quality paint. Spray or brush it on evenly.

- Apply Coating: After the paint dries, add a clear coat. This adds extra protection and shine.

Make sure to let each layer dry completely before applying the next. This ensures a smooth and lasting finish.

Adding Accessories

Adding accessories can enhance the steel drum’s functionality and appearance. Here are some common accessories:

- Rubber Feet: These prevent the drum from slipping.

- Handles: Attach handles for easy carrying.

- Drum Stand: A stand provides a stable platform for playing.

- Drum Case: A padded case protects the drum during transport.

Each accessory adds value and convenience for the player. Choose the ones that best suit your needs.

Care And Maintenance

Proper care and maintenance are vital for keeping your steel drum in top condition. Regular upkeep ensures the instrument sounds great and lasts longer. Let’s explore some essential care tips.

Regular Cleaning

Always clean your steel drum after playing. Use a soft cloth to remove dirt and oil. This prevents rust and keeps the drum shiny. Avoid using harsh chemicals. Mild soap and water work best. Dry the drum thoroughly after cleaning. Moisture can cause damage over time.

Proper Storage

Store your steel drum in a cool, dry place. Avoid direct sunlight, which can warp the metal. Use a padded case for extra protection. This prevents scratches and dents. Keep the drum away from extreme temperatures. Hot or cold environments can affect its tuning.

Credit: www.instructables.com

Frequently Asked Questions

What Materials Are Needed To Make A Steel Drum?

To make a steel drum, you need an oil barrel, a hammer, a tuning stick, and a mallet.

How Long Does It Take To Make A Steel Drum?

Making a steel drum can take several hours to a few days, depending on skill level.

What Is The Process Of Tuning A Steel Drum?

Tuning a steel drum involves shaping and hammering the metal to create precise pitches for each note.

Can Beginners Make A Steel Drum?

Yes, beginners can make a steel drum with guidance, patience, and the right materials and tools.

Conclusion

Crafting a steel drum involves patience and skill. From selecting the right barrel to tuning each note, every step matters. Practice improves your technique. Enjoy the process and the music you create. Making a steel drum is a rewarding experience.

Share your music with others. Continue learning and experimenting. Your unique sound will develop over time. Enjoy making music with your handcrafted steel drum.

{ “@context”: “https://schema.org”, “@type”: “FAQPage”, “mainEntity”: [ { “@type”: “Question”, “name”: “What materials are needed to make a steel drum?”, “acceptedAnswer”: { “@type”: “Answer”, “text”: “To make a steel drum, you need an oil barrel, a hammer, a tuning stick, and a mallet.” } } , { “@type”: “Question”, “name”: “How long does it take to make a steel drum?”, “acceptedAnswer”: { “@type”: “Answer”, “text”: “Making a steel drum can take several hours to a few days, depending on skill level.” } } , { “@type”: “Question”, “name”: “What is the process of tuning a steel drum?”, “acceptedAnswer”: { “@type”: “Answer”, “text”: “Tuning a steel drum involves shaping and hammering the metal to create precise pitches for each note.” } } , { “@type”: “Question”, “name”: “Can beginners make a steel drum?”, “acceptedAnswer”: { “@type”: “Answer”, “text”: “Yes, beginners can make a steel drum with guidance, patience, and the right materials and tools.” } } ] }

As an Amazon Associate, Cleanestor earns from qualifying purchases at no additional cost to you.